![]()

Applied Analytics, Inc. is a global supplier of online analysis equipment serving the oil, natural gas, chemical, and pharmaceutical industries. For over 20 years, AAI has provided efficient and economical solutions to the most challenging industrial applications using UV-Vis and NIR spectroscopy. AAI’s flagship OMA-300 process analyzer and TLG-837 tail gas analyzer help comprise the comprehensive product line that suits many analytical requirements.

The TLG-837 tail gas analyzer continuously measures the chemical concentrations of H2S, SO2, COS, and CS2 in the Claus process tail gas stream. Using the patented in situ DEMISTER sampling probe and a full-spectrum UV-Vis spectrophotometer, this system provides extremely fast, accurate response for tight process control.

Features:

- Continuously measures concentrations of H2S and SO2 (H2S/SO2 ratio) and outputs Air Demand signal (user-defined formula)

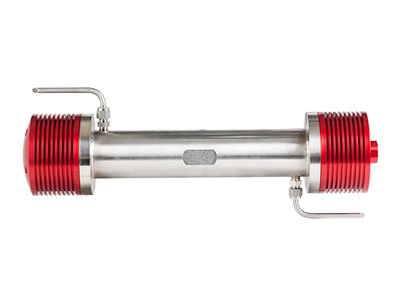

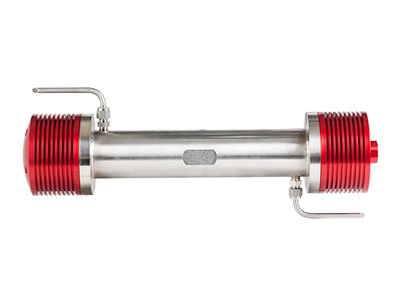

- Patented DEMISTER sampling probe with internal sulfur vapor removal

- Totally solid state with no moving parts, sample lines, or heat tracing – modern design for low maintenance

- Ultra-safe fiber optic design – no toxic/explosive sample gas in analyzer enclosure

- Superior Off-Ratio range ( 100:1 < H2S/SO2 ratio < 1:20 )

Measurements:

- H2S

- SO2

- COS

- CS2

- air demand

The OMA is an industrial device which measures a high-resolution absorbance spectrum in a continuously drawn sample from a liquid or gas process stream. Harvesting this rich data, the OMA process analyzer provides real-time analytics for the process stream, including chemical concentrations, purity, and color.

Chemical Concentrations:

The OMA can simultaneously monitor up to 5 chemicals in the sample stream. All analytes must have distinct absorbance curves in the 200-1100nm UV-Vis/SW-NIR wavelength range to be measurable by the OMA.

Chemical Purity:

By measuring a high-resolution transmittance spectrum, the OMA can very precisely detect impurities in the sample fluid by sudden changes in the spectral structure.

Physical Properties:

Various properties such as the heating value of a fuel or the octane of a gasoline blend can be powerfully correlated to the absorbance spectrum of the sample.

Specialized OMA Solutions:

- Ammonia Analyzer

- BTX Analyzer

- Chlorine Analyzer

- Clean-in-Place Analyzer

- Color Analyzer

- Continuous Emissions Analyzer

- H2S Analyzer

- Metal Ions Analyzer

- NOx Analyzer

- Odorant Analyzer

Two Explosion-proof Formats:

- Eexp – Eexp systems are purged and pressurized using a certified air-purging device. This method ensures that toxic/explosive gas is not allowed to accumulate inside the enclosure, and is ideal when instrument air is available.

- Eexd – Eexd systems are contained within certified explosion-proof cast-aluminum enclosures. This method is more practical if the installation is remote or utilities are unreliable.

Other OMA Models:

- OMA-206P Portable – The portable version of the OMA Process Analyzer is housed in an ultra-rugged suitcase enclosure, so you can bring analytics from site to site with confidence.

- OMA-406R Rackmount – The rackmount version of the OMA is designed for easy integration in analyzer shelters and laboratory settings.

The OMA H2S analyzer continuously measures H2S concentration using a full-spectrum UV-Vis spectrophotometer, harvesting the power of collateral data to establish excellent dynamic range and sustain accuracy in the presence of cross-interfering species. With an ultra-safe fiber optic design and solid state build, this system is simple to install and relentlessly reliable.

Features:

- Continuously measures H2S concentrations in a liquid or gas process stream

- Up to 4 additional software benches for additional analytes (e.g. SO2 , R-SH)

- Totally solid state build with no moving parts – modern design for low maintenance

- Ultra-safe fiber optic design with dedicated sample flow cell – no toxic/corrosive sample fluid in analyzer enclosure

- Decades of field-proven performance in the world’s harshest industrial environments

From the MicroSpec series comes the MCP-200, a concentration monitor for species that absorb IR radiation. This solid state package combines a non-dispersive IR detector and a proprietary optical path design. Engineered to be compact and modular, the MCP-200 excels as both a rugged standalone and an integrated component.

Measurements:

- carbon monoxide | CO

- carbon dioxide | CO2

- ethylene | C2H4

- methane equivalency | CH4

- water | H2O

The automated gas mixing system from Applied Analytics utilizes cutting-edge mass flow controllers to achieve the precision and repeatability required for demanding applications like research and instrument calibration.